Description of Aseptic bag in Box filler

This equipment is our own R&D equipment with innovation patent specially developed by our company for 1-30L sterile bags. It is mainly used for filling and filling aseptic pouches of fruit and vegetable products such as NFC juice, puree, jam, milk, concentrated juice jam, etc. NFC orange juice, apple juice, mango pulp, ketchup, etc.

The working process of BIB filling machine: Power supply → set filling volume → manual bag loading → start switch → automatic bag clamping → automatic cap pulling → automatic weighing filling → automatic cap moving → automatic cap pressing → automatic bag out

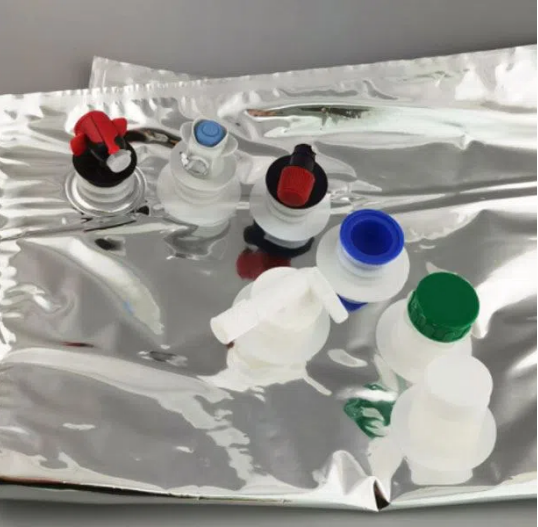

Filling bag mouth type:1 inch ordinary mouth, spiral mouth, butterfly valve mouth

Characteristics of the Bag in Box filling machine

l The aseptic filling machine comes with a sterile room, and uses three-point spray sterilization of the bag mouth, filling head and filling chamber with sterile steam to ensure the sterility requirements during the filling process.

l The sterilization, opening, filling and sealing of the aseptic bag mouth are all done in a sterile environment.

l The filling speed is fast, the material returns less, and the production efficiency is high.

l Made of all stainless steel materials, in line with food hygiene standard.

l And front-end sterilization machine online control, to achieve CIP and SIP.

l The metering method can be metered or weighed according to the physical properties of the material, and the filling accuracy is high.

l The filling chamber is uniquely designed to avoid condensation and water droplet leakage;

l Easy to operate and easy to maintenance

Main parameters of the aseptic bag in box filling machine

| Model | LZ-BIB-1 | LZ-BIB-2 |

| Filling Range | 1-50L | 1-50L |

| Maximum Filling Speed | 250bags/hour(1L) | 450bags/hour(1L) |

| 200bags/hour(2L) | 380bags/hour(2L) | |

| 150bags/hour(5L) | 280bags/hour(5L) | |

| 120bags/hour(10L) | 220bags/hour(10L) | |

| 100bags/hour(20L) | 180bags/hour(20L) | |

| Filling Precision | 99.5% | 99.5% |

| Compressed Air Pressure | ≥0.7MPa | ≥0.7MPa |

| Compressed Air Consumption | 10M3/H | 20M3/H |

| Steam pressure | ≥0.5 MPa | ≥0.5 MPa |

| Compressed Air Consumption | 20KG/H | ≥0.5 MPa 40KG/H |

| Power | 1KW | 1.5KW |

| Dimension (l*w*h) | 1300*1100*1800mm | 2500*1100*1800mm |

Duplex filter

Duplex filter Horizontal centrifuge

Horizontal centrifuge Double head BIB(bag in box) aseptic filling mac...

Double head BIB(bag in box) aseptic filling mac... Disk centrifuge

Disk centrifuge Ton box aseptic filling machine

Ton box aseptic filling machine Single head BID(bag in drum) aseptic filling ma...

Single head BID(bag in drum) aseptic filling ma...