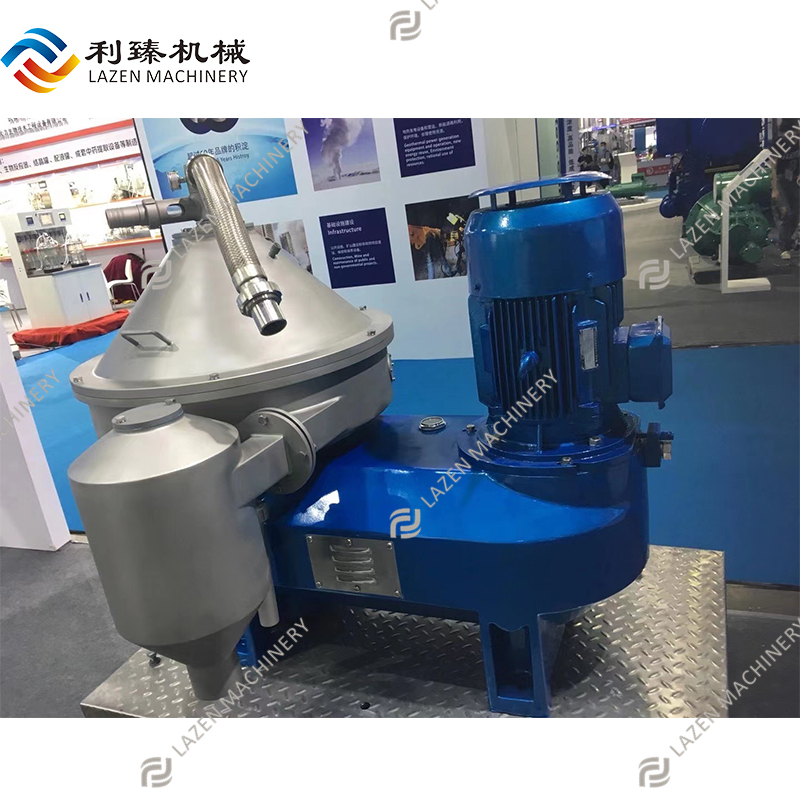

Introduction of Disc centrifugal machine

Disc separator is the newest generation separator for milk , mainly used to purify of milk, juice, beverage, Chinese traditional medicine and chemical industry etc.

It adopt small piston structure for gaining variable discharging capacity, and PLC control both partly and fully discharging in order to get rid of sediment.

The clear liquid is pumped out by centripetal pump, the sludge is discharged automatically and partly.

Working principle of the Disc centrifugal

Fruit juice is fed into the drum through a feed pipe located in the center of the drum. When the juice flows through the gap between the discs, the solid particles (or droplets) sink to the discs under the action of the centrifuge to form sediment (or liquid layer). Sediment slides along the surface of the disc, separates from the disc and accumulates in the largest diameter part of the drum, and the separated liquid is discharged from the drum through the liquid outlet. The function of the disc is to shorten the settling distance of solid particles (or liquid droplets) and expand the settling area of the drum. As the disc is installed in the drum, the production capacity of the separator is greatly improved. Solids accumulated in the drum are disassembled and manually removed after the separator stops, or discharged from the drum without stopping by the slag discharging mechanism.

Main features of Disc centrifugal machine

The machine adopts automatic control, it has the advantages of high efficiency, low materiel consumption, convenient operation and economic maintenance cost.

The machine is one kind of rotary machine with high speed, After accurate dynamic balancing, it can run for long time with low vibration, safety and security.

Main Technical Specification of Disk

|

Discharging type |

variable capacity discharging |

|

Driving mode |

belt drive |

|

Processing capacity |

2000L/h |

|

Outlet pressure of clear liquid |

≤0.2 MPa |

|

Motor power |

5.5kw |

|

Dimension (l*w*h) |

844mm×777mm×1038mm |

|

G.W. |

664kg |

Single head BIB(bag in box) aseptic filling mac...

Single head BIB(bag in box) aseptic filling mac... BIB filler

BIB filler Duplex filter

Duplex filter Single head BID(bag in drum) aseptic filling ma...

Single head BID(bag in drum) aseptic filling ma... Double head BID(bag in drum) aseptic filling ma...

Double head BID(bag in drum) aseptic filling ma... Double head BIB(bag in box) aseptic filling mac...

Double head BIB(bag in box) aseptic filling mac...