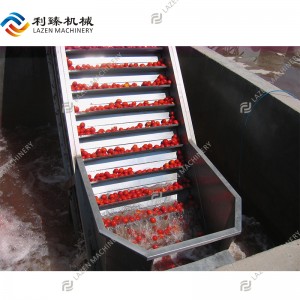

Description of Fruit elevator

The scraper elevator uses 304 stainless steel plate to transport and lift fruits and vegetables. The mesh plate can be perforated according to the size of customers' fruits and vegetables. The main power is continuously variable and suitable for different working conditions. Equipped with main and driven bearing, the spray cleaning nozzle can be added for washing fruits and vegetables. The scraper / clapboard divides the materials into small parts and intermittently transports them to the next station for further treatment, which solves the problem of stacking and blocking from the belt conveyor to the receiving machine.

Main Characteristics Of Fruit Elevator

① The scraper elevator is suitable for lifting and conveying various fruits such as pomegranate, coconut, apple, citrus, pineapple, mango, peach, carrot, tomato, onion and other vegetables.

② Stainless steel bracket, food grade hard plastic or stainless steel scraper, in line with food hygiene standards;

③ Anti-card fruit smoothing scraper water seepage structure, stable operation, low voice;

④ Adopt foreign imported anti-corrosion bearings, double-sided sealing;

⑤ Low operating cost, variable frequency speed regulation;

⑥ The water-bearing material such as fruits can be raised to a certain height along an inclined angle of 45° to the bottom surface;

⑦ The fruit processing line can be combined with equipment such as fruit detectors and washing machines.

⑧ Low energy consumption: The machine uses friction in the material to transport, and the conveyor chain and the casing move without friction. Under the same conveying capacity and longer conveying distance, the power consumption of this machine is about 40% lower than that of the screw conveyor.

Main model and parameters of fruit elevator

|

Model |

Capacity (T/H) |

Power(KW) |

Dimension(MM) |

|

LZ-FE-800 |

1~3 |

1.1 |

6000*800*450 |

|

LZ-FE-1000 |

3~5 |

1.5 |

6000*1000*450 |

|

LZ-FE-1300 |

8~10 |

3 |

6000*1300*450 |

|

LZ-FE-1600 |

13~15 |

5.5 |

6000*1600*450 |

Main Characteristics Of Screw Conveyor

① This machine uses the reducer to drive the spiral rotation and shift the material to achieve the purpose of transportation;

② In addition to the bearing of the power unit, the rest of the structure is all stainless steel, in line with food hygiene standards;

③ It has the advantages of simple structure, small cross-sectional area, convenient sealing and transportation, multi-point feeding or unloading; Shell type: "O type" or "U type" Spiral form: no shaft, single shaft or multiple shaft;

④ Simple structure, convenient for closed transportation, multi-point feeding or unloading;

⑤ The inside of the spiral can be added with a flushing water pipe to facilitate the cleaning inside the screw.

Main model and parameters of screw conveyor

|

Model |

Capacity (T/H) |

Power(KW) |

Dimension(MM) |

|

LZ-SC-300 |

1~3 |

1.1 |

6000*300*300 |

|

LZ-SC-350 |

3~5 |

1.5 |

6000*350*350 |

|

LZ-SC-400 |

8~10 |

3 |

6000*400*400 |

|

LZ-SC-450 |

13~15 |

4 |

6000*450*450 |

Screw type juice extractor

Screw type juice extractor Crushing machine

Crushing machine Aseptic bag in drum filler

Aseptic bag in drum filler Fruit receiving system

Fruit receiving system Fruit destoning and pulping machine

Fruit destoning and pulping machine Pulping & refining machine

Pulping & refining machine