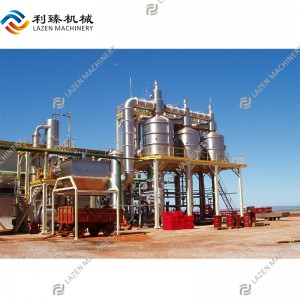

Description of forced circulation vacuum evaporator

l Forced circulation evaporator is specially applied to the evaporation concentration of materials with high viscosity, heat sensitive and high insoluble solid content such as jam (tomato paste/ketchup/mango puree/peach paste/apricot paste/strawberry jam/chili sauce, etc. and syrup.

l It is mainly composed of tube heater, vacuum evaporation chamber, multi-stage condenser, pump (material circulation pump / vacuum pump / water pump), automatic PLC control system, related valve group and detection instrument, operating platform and other components.

l It is highly customized, single-effect, two-effect and multi-effect evaporators can be designed according to customer's production requirements and product characteristics.

Features of forced circulation vacuum evaporator

1. Continuous vacuum condensation under vacuum conditions ensures minimal loss of active ingredients in the material.

2. The main structure is made of high quality stainless steel 304/316 and meets food hygiene standards;

3. The evaporator passes through the forced circulation to heat evenly in the membrane tube to prevent fouling;

4. Energy-saving and consumption reduction, the secondary steam separated by the first-effect separator enters the second-effect heater for heating, and the secondary steam separated by the second-effect separator enters the condenser to condense, so the heat is reused and the steam is greatly saved Consumption, while also saving cooling water circulation.

5. Low-temperature concentration. The entire evaporation process of this equipment is in a vacuum state, which reduces the evaporation temperature of the material, making the material difficult to scale during the heating and evaporation process, and can better meet the requirements for the concentration of heat-sensitive fruit juice, Chinese medicine, western medicine and heat-sensitive materials.

6. Fully automatic control can be implemented to monitor and record key control points such as sugar content;

7. It has the advantages of compact structure, stable operation, high efficiency and energy saving.

Technical specifications of Forced circulation vacuum evaporator

| Model: |

LZ-DEFE-3 |

LZ-DEFE-5 |

LZ-DEFE-10 |

LZ-TEFE-20 |

LZ-FEFE-30 |

| Water evaporation(L/hr): |

1000-3000 |

3000-5000 |

5000-10000 |

10000-20000 |

20000-30000 |

| Steam consumption(T/hr) |

1.25-1.65 |

2-2.75 |

4-5.5 |

8-11 |

12-16.5 |

| Steam pressure(Mpa): |

0.5-0.8 |

||||

| Power(kw): |

20-60 |

60-100 |

100-160 |

160-200 |

200-280 |

| Dimension(m):

(L*W*H) |

6.7*4.4*8.6 |

7.2*4.8*11.5 |

8.5*5.4*11.5 |

9.6*6*13.5 |

13*6.5*13.5 |

MVR evaporator

MVR evaporator Forced circulation evaporator

Forced circulation evaporator Forced circulation evaporator

Forced circulation evaporator Fallingfilm evaporator

Fallingfilm evaporator Fallingfilm evaporator

Fallingfilm evaporator Falling film evaporator

Falling film evaporator