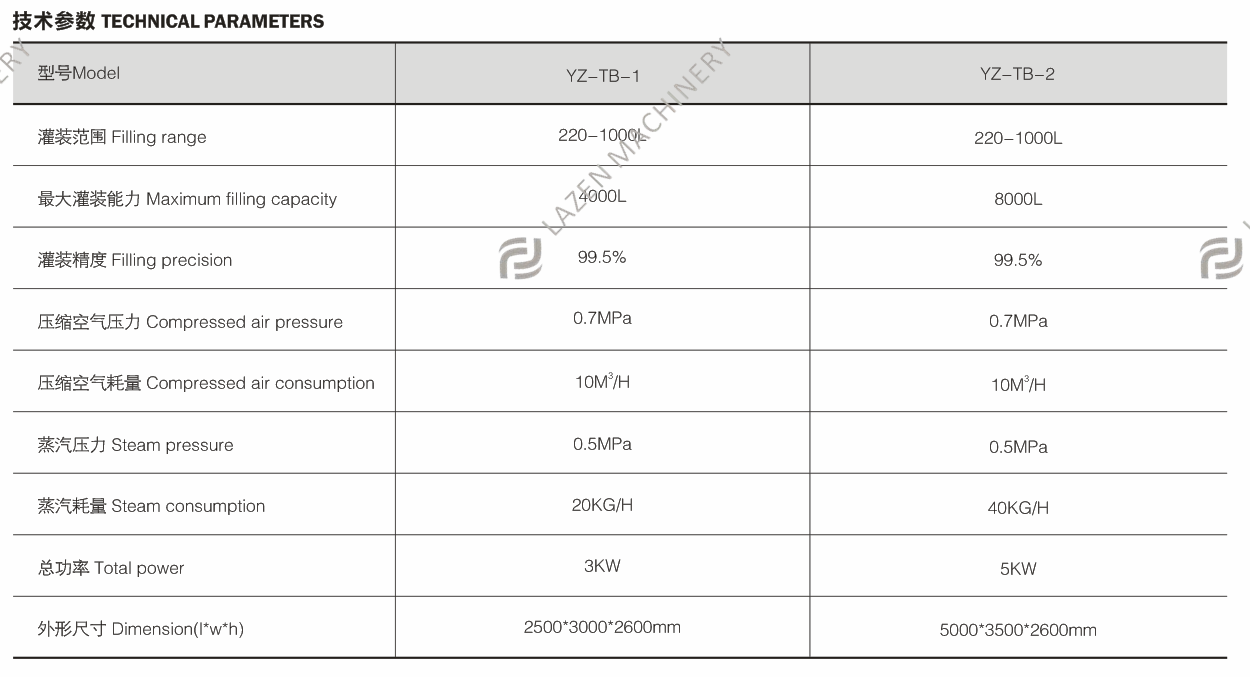

EQUIPMENT INTRODUCTION

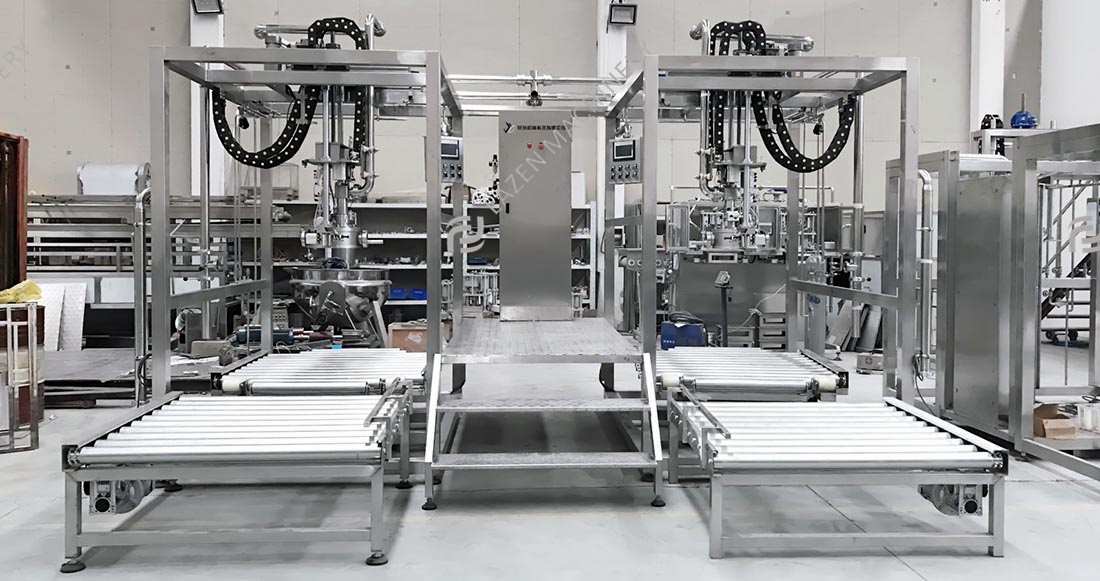

The ton box aseptic filling machine is suitable for aseptic filling of fruit and vegetable juice, jam or their concentrated products, dairy and other viscous and non-viscous fluids. It is mainly composed of the aseptic filling head, lifting system, human-machine control system, steam protection system, metering system, rotary pallet (can be used for four 220L barrels), roller conveying system, etc. The steam jetting mode is adopted in the filling cavity to always maintain high temperature and positive pressure and ensure that the filling room is continuously in an aseptic status and filling and sealing are completed in an aseptic environment.

MAIN FEATURES OF EQUIPMENT

◆It is made of high quality SUS304 or 316L stainless steel except the motor, electrical appliance and soft connections.

◆It is suitable for aseptic filling of 220L-1000L aluminum-plastic composite aseptic bags.

◆It is equipped with condensing water collector to avoid dripping and leakage of condensing water.

◆The material pipe is provided with steam shielding devices at the flexible joints. Steam sterilization is adopted in the filling room to continuously maintain sterility and ensure safe filling.

◆The main parts are products of world famous brands, such as touch screen and PLC of Siemens, flow meter of Krohne.

◆Manual bag feeding, one-key bag clipping, one-key filling, automatically sent out of the workshop after filling.

Single head BID(bag in drum) aseptic filling ma...

Single head BID(bag in drum) aseptic filling ma... Double head BID(bag in drum) aseptic filling ma...

Double head BID(bag in drum) aseptic filling ma... Single head BIB(bag in box) aseptic filling mac...

Single head BIB(bag in box) aseptic filling mac... Double head BIB(bag in box) aseptic filling mac...

Double head BIB(bag in box) aseptic filling mac...