1. Description of apple/pear processing line

Fresh apple and pear can be processed to apple/pear pulp,puree, NFC juice, HPP juice,clear concentrate juice, paste, sauce,etc;

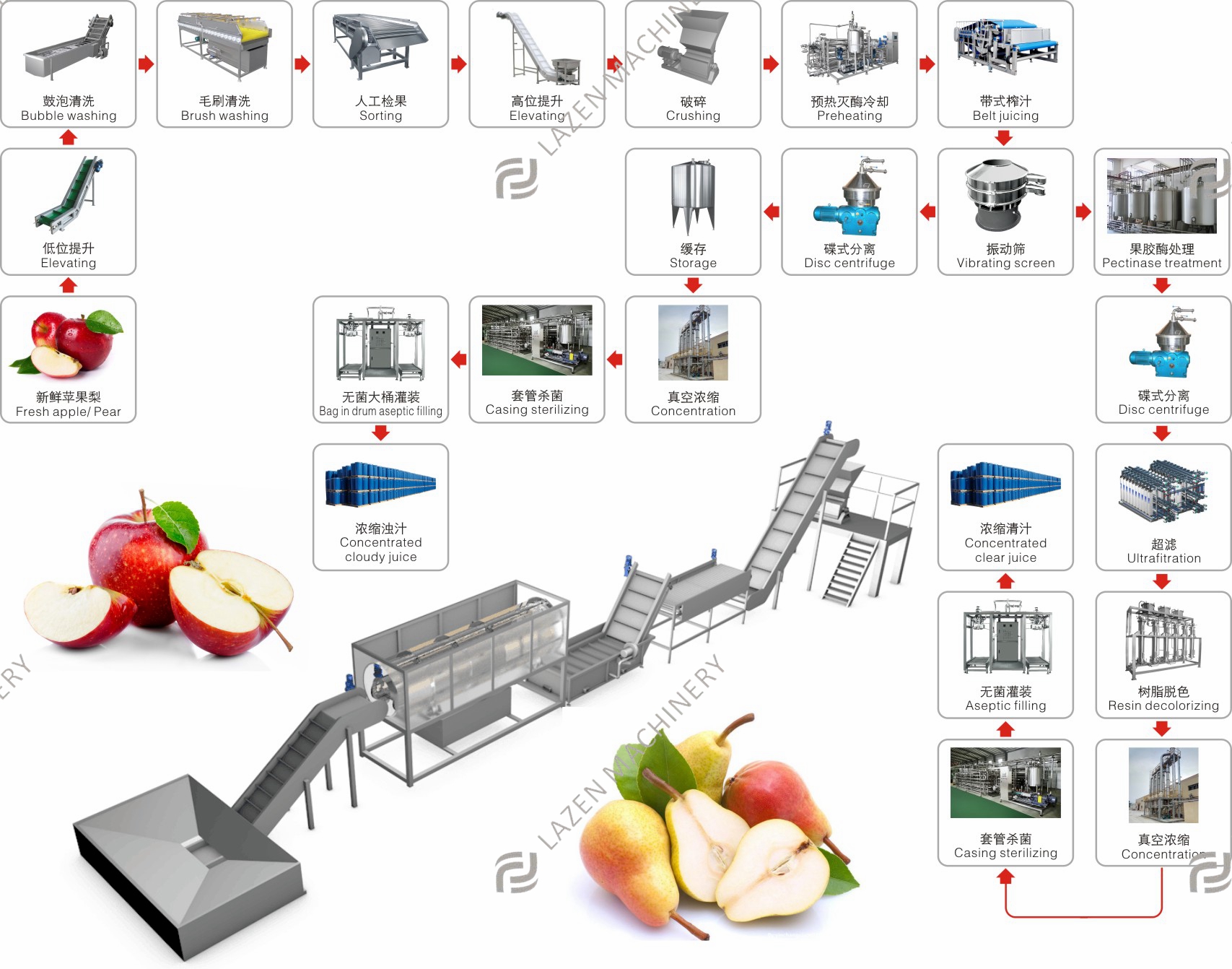

The apple and pear processing includes washing and sorting system,crushing and color protection system, juice /pulp extracting system, decanting and standardization system, enzymatic hydrolysis and filtration system, evaporating system, sterilizing system and aseptic filling system.

Apple/pear processing line capacity is from 24 tons/day-480tons/day.

Apple/pear Juice yield: about 75% (25% for fruit peels and cores for the waste)

Raw material solid content: 12-14Brix,Final concentrated juice concentration: 65 ~ 72Brix, concentrated apple paste 28-30Brix.

2. Features of apple/pear processing line

Advanced technology and energy saving.

SUS304/316L material,high qualified component of international brand.

Semi-automatic as well as fully automatic system available.

Customized turn-key solution including installation, commissioning at your side.

The finished product quality is excellent, and the color is delicious.

High productivity, flexible production, can be customized according to customer demand.

Complete supervision system, equipped with control room to monitor each processing stage.

Daily output can be clearly revealed.

3.Specification of apple/pear processing line

|

Raw material |

Fresh apple,pear |

|

End product |

Concentrated juice, clear juice,puree,cloudy juice |

|

Processing capacity |

From 24tons/day to 2000 tons/day |

|

Efficient input |

75% raw fruit (25% as waste,peels and seeds) |

|

Fruit consistence |

10-12Brix |

|

Product consistence |

65-72Brix for concentrated juice |

|

End package |

Aseptic bag/tin can/glass bottle/PET bottle |

|

Output |

Can be calculated |

4. Flowchart of apple/pear processing line

5. End package

6. Reference pictures of apple/pear processing line

Pineapple processing line

Pineapple processing line Pumpkin processing line

Pumpkin processing line Citrus processing line

Citrus processing line Coconut processing line

Coconut processing line Dried fruits production line

Dried fruits production line Avocado processing line

Avocado processing line