EQUIPMENT INTRODUCTION

The aseptic large bag filling machine is mainly composed of the aseptic filling head, metering system, roller conveying system, human-machine interface and PLC control system, operation platform, etc. It is specially used for filling of 5-220L aseptic bags. The steam jetting mode is adopted in the filling cavity to always maintain high temperature and positive pressure. The sterilizing, opening, filling and sealing of the aseptic bag mouth are carried out in an aseptic environment. It is equipped with condensing water collector to avoid dripping and leakage of condensing water. The equipment is widely applied in such industries as fruit juice, jam, dairy, chemical industry, etc.

MAIN FEATURES OF EQUIPMENT

◆It is made of high quality SUS304 or 316L stainless steel except the motor, electrical appliance and soft connections.

◆It is suitable for bags of different sizes and volumes (5-220L), making production more flexible.

◆Two metering systems are available for selection: weighing measurement or flow meter measurement, with accurate measurement.

◆The material pipe is provided with steam shielding devices at the flexible joints. Steam sterilization is adopted in the filling room to continuously maintain sterility and ensure safe filling.

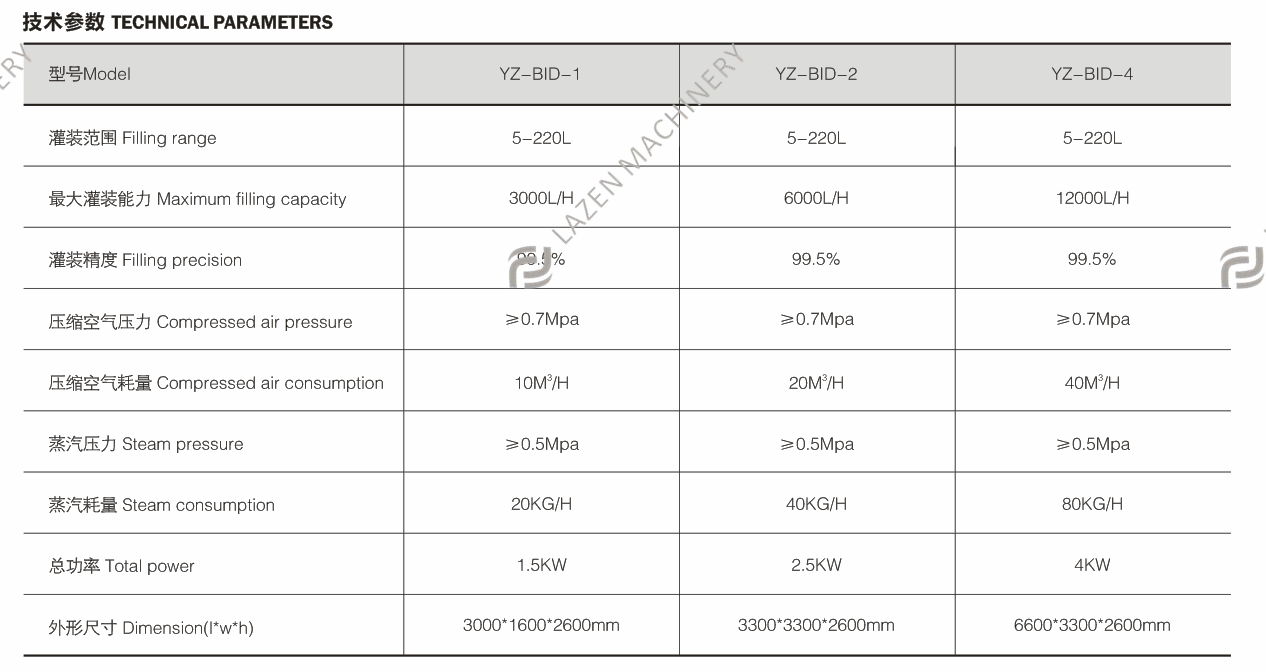

◆Multi-head aseptic filling machines (1-head, 2-head, 4-head, etc.) can be customized according to customer needs, so as to facilitate its use with sterilizers of high production capacity.

Ton box aseptic filling machine

Ton box aseptic filling machine Double head BIB(bag in box) aseptic filling mac...

Double head BIB(bag in box) aseptic filling mac... Single head BID(bag in drum) aseptic filling ma...

Single head BID(bag in drum) aseptic filling ma... Single head BIB(bag in box) aseptic filling mac...

Single head BIB(bag in box) aseptic filling mac...