1. Description of the tomato juice/puree processing line:

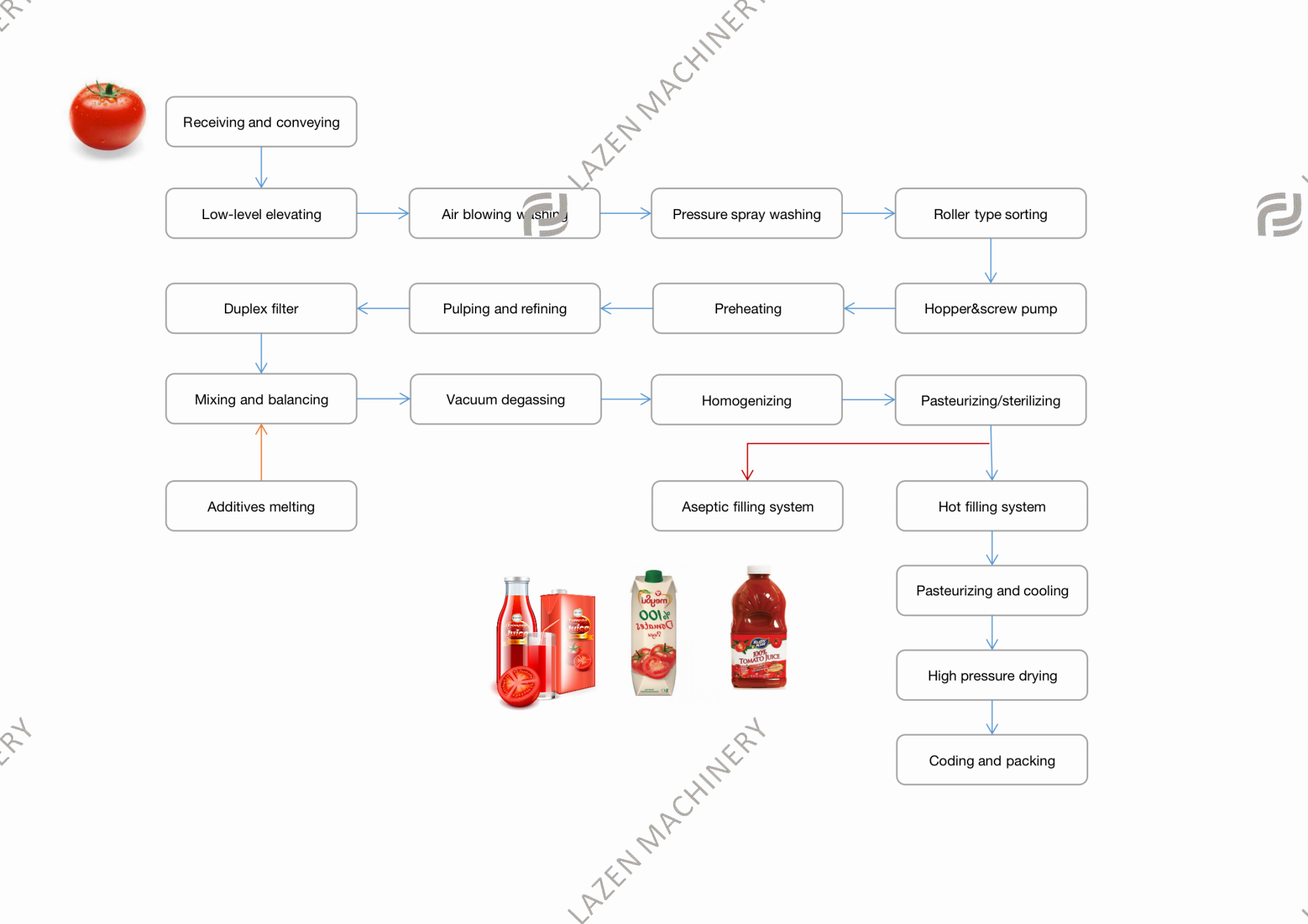

Tomatoes are usually processed for paste and the processing line mainly includes five parts: fresh tomato receiving, pre-washing and sorting section,crushing and pulping section, mixing and standardization section, degassing and homogenizing section, pasteurizing or sterilizing section, filling section, pasteurizing and cooling section, packing section,auxiliary energy section.

The tomato juice or puree brix is 4-4.5%.

Tomato juice can be filled into can, bottle, doypacks,tera pack, stand-up pouch,etc.

2. Features of tomato paste processing line

Advanced technology and energy saving.

SUS304/316L material,high qualified component of international brand.

Semi-automatic as well as fully automatic system available.

Customized turn-key solution including installation, commissioning at your side.

The finished product quality is excellent, and the color is delicious.

High productivity, flexible production, can be customized according to customer demand.

Complete supervision system, equipped with control room to monitor each processing stage.

Daily output can be clearly revealed.

3. Specification of the tomato processing line:

|

Raw material |

Fresh tomato |

|

End product |

Tomato juice/puree |

|

Processing capacity |

From 60tons/day to 2000 tons/day |

|

Efficient input |

90% raw fruit (10% as waste,peels and seeds) |

|

Fruit consistence |

4-4.5Brix |

|

End package |

Can/bottle/doypack/stand-up pouch/tera pack |

|

Output |

Can be calculated |

4. Flowchart of tomato juice/puree processing line

5. End package

6. Reference pictures of tomato juice/puree processing line

Canned French Beans Production Line

Canned French Beans Production Line Guava processing line

Guava processing line Mango processing line

Mango processing line Citrus processing line

Citrus processing line Banana proceesing line

Banana proceesing line Tomato sauce ketchup processing line

Tomato sauce ketchup processing line