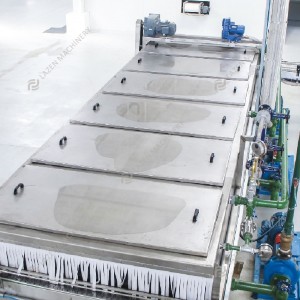

Description of spray type pasteurizing and cooling tunnel

The spray type pasteurization and cooling tunnel uses circulating warm water spray for preheating, circulating hot water spray for pasteurization, warm water pre-cooling, cold water cooling stage by stage treatment, pasteurizing and cooling beverage to ambient temperature and sent to the next station for further processing. The whole process is fully automatic, pasteurization and cooling time can be designed according to requirements. It is applied to pasteurizing and cooling of various bottled and canned beverages, fruit juice, pulp,sauce, etc.

Features of spray type pasteurizing and cooling tunnel

It is mainly made of stainless steel which with insulation on both sides.

The pasteurization temperature is controlled accuracy

3. The total processing speed is controlled by frequency conversion, which can be adjusted according to the production process;

4. Configure automatic feeding and discharging mechanisms for non-circular PP bottles, plastic bags, roof cartons, glass bottles, cans and other products, and the connection to the conveyor line is smooth.

5. It can be widely used in the pasteurization and cooling of various bottled and canned acid juice drinks, electrolyte drinks, alcohol, condiments and other products;

This equipment can be designed according to the sterilization conditions and output requirements of users.

6. The spraying hot water and cooling water can be recycled for use, which is saved water, electricity and steam greatly.

Technical specifications

| Model: |

LZ-SPCT-1000 |

LZ-SPCT-2000 |

LZ-SPCT-3000 |

LZ-SPCT-5000 |

| Pasteurization temperature: |

85~96℃ |

|||

| Steam pressure(Mpa): |

0.4~0.6 |

|||

| Conveying speed(mm/min): |

110~553 |

|||

| Hot water consumption (L/H): (recycle) |

21 |

25 |

35 |

50 |

| Power(kw): |

9.6 |

10.6 |

13.6 |

16.5 |

| Dimension(m):

(L*W*H) |

9800*2250*1730 |

17800*2250*1730 |

23800*2250*1730 |

34800*2250*1730 |

Double head BIB(bag in box) aseptic filling mac...

Double head BIB(bag in box) aseptic filling mac... Tubular sterilizer

Tubular sterilizer Tubular sterilizer

Tubular sterilizer Forced circulation evaporator

Forced circulation evaporator Fruit destoner

Fruit destoner Bubble washer and elevator

Bubble washer and elevator